Types of Setup

Two-bed deionized water systems

In the two bed deionizers setup it provides higher exchange capacity with less complicated operating procedure compared to mixed bed systems. In a dual bed deionizer, the cation and anion exchangers are connected in series.

The cation tank removes positively charged ions (calcium, sodium, magnesium, iron, manganese and potassium). The anion tank removes negatively charged ions (sulfates, chlorides, carbonates, bicarbonates, nitrates and silica). Strong base anion units typically produce 0.2 megohm water at a pH of 8-9, whereas weak base anion units produce lower water quality, a pH of 6-7, and do not remove silica or CO2.

Mixed-bed deionized water systems

In the Mixed bed deionizers setup it provides higher water quality, lower rinse water requirements, and more neutral pH than Two- bed systems. In a mixed bed deionizer, cation and anion resins are combined and mixed in a single tank. Thousands of cation and anion ion exchanges take place as water passes through the resin bed. Typical water quality of 16 megohm or more with neutral pH.

Multiple-tank deionized water systems

In the Multiple-tank setup commonly three tanks or more are connected in series; or parallel; or a combination of the two. Produces high purity water in any desired quantity. Systems may consist of strong acid cation, strong or weak base anion and mixed bed media tanks in a number of varying combinations, to produce the water quality required. Water qualities of 18 megohm, with a neutral pH, can typically be attained.

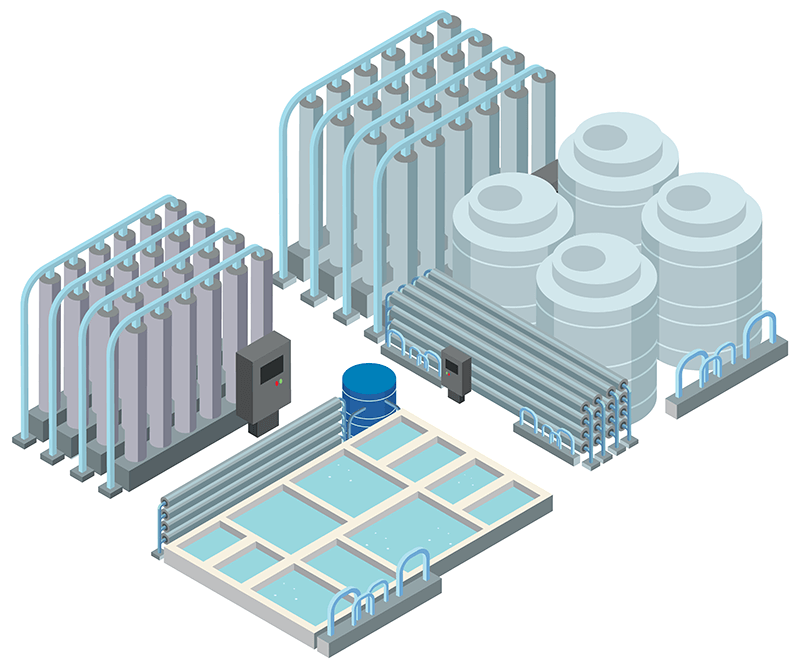

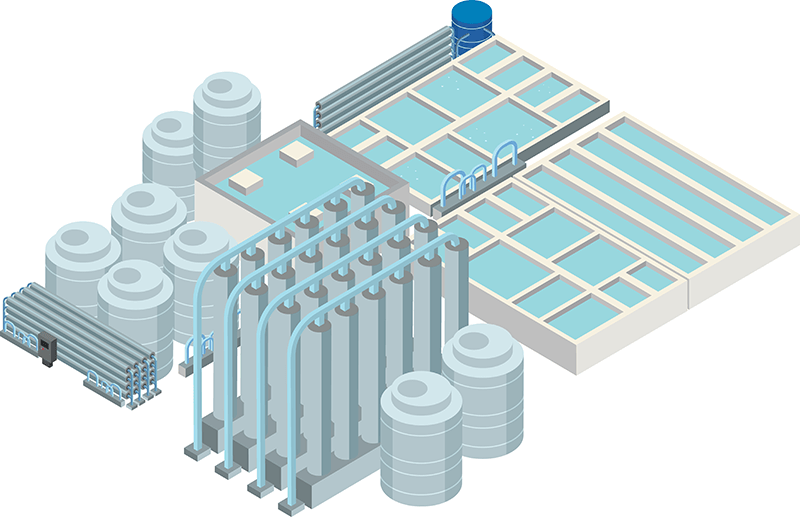

Complete multiple-process treatment systems

In this setup the exchange service tanks and other water treatment media is use to create a more complete high purity water system. Typically, a system may include one or more of the following processes: softening, depth filtration, carbon adsorption, UV sterilization, submicron filtration, or other treatment equipment.

Typical Components include:

- Water softener

- Carbon filter

- Reverse osmosis unit

- Storage vessel

- Di (deionization) system

- Bacteria control equipment

- High-purity piping system

Frequently Asked Questions (FAQs)

What are the cost of deionized water?

It depends on the overall system primarily based on the quantity of the DI water and quality(standard that needs to be met). DI water can normally be provided per exchange or on a cents per gallon basis. The system cost includes DI canisters and water quality equipment.

How is deionization resin used?

Deionized water resin is either used as a main treatment component or a polishing component in the water treatment system.

As we mentioned earlier, Total Water uses single-tank regeneration, so the resin is always assigned to a specific tank for traceability. This improves the quality of the di water. Some suppliers provide bulk di resin, which eliminates the traceability and lowers the purity.

What is the Ph of deionized water?

When you have 18 megohoms resistivity, your deionized water ph can only be 7. “pH” is the percent of hydrogen in the water.

Does Total Water sell a deionized water filter?

Many people think you can buy a di water filter, but that’s not the case. It’s a process, in which one ion is exchanged for another. The process is explained in the next section.

How do you make deionized water? Is there a deionized water chemical formula?

The chemical formula for deionized water involves the exchange of the charged ions in tap water for hydrogen and hydroxl ions. Water in its purest form is hydrogen (H+) and hydroxl (OH-) ions, which form the water molecule, H2O.

Does di water cause corrosion of pipes?

Pure Water measured at 18.2 Megohm is normally run through a pipe made of polypropylene or PVDF. There is a misconception that di water cannot be corrosive to stainless steel piping. This is incorrect, stainless steel piping will break down over time when used in high purity water systems. As the stainless steel loses it’s passivation it begins to leach iron into the purified water stream.